Hobaneng ho na le likoripi tse monate tse bohlokoa bakeng sa ts'ebetso ea mei ea liindasteri?

2025-10-10

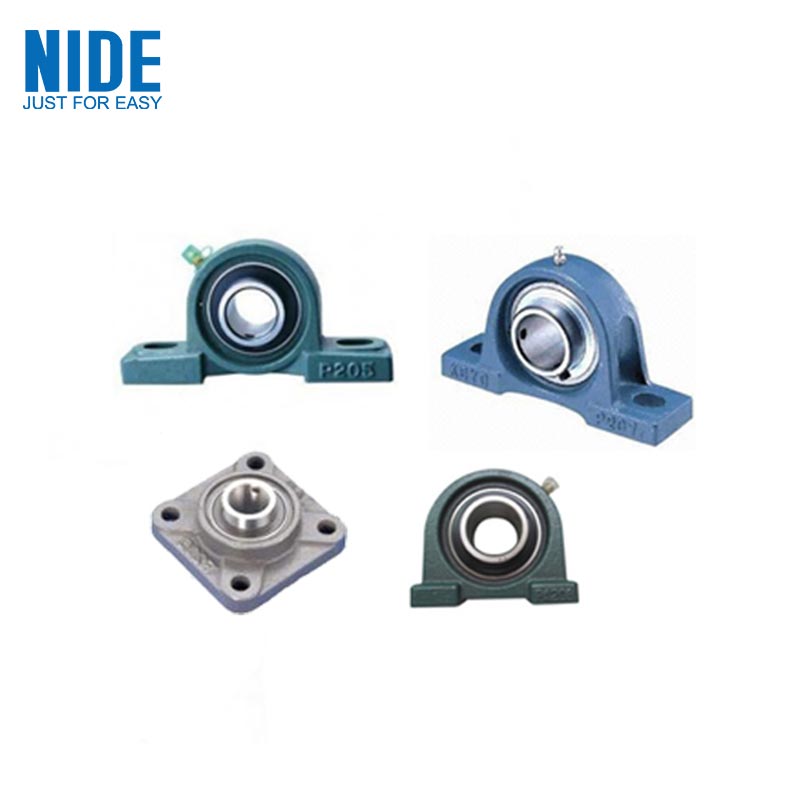

Lefatšeng la boenjiniere ba mechini le indasteri,Lipere tsa PhotoeringBapala karolo ea bohlokoa ho netefatsa ts'ebetso e boreleli le e sebetsang ea lisebelisoa tse potolohang. Ebang e sebelisoa ho Thehana, Bahale ba Motlelete, Mechine ea temo, Mechine ea temo

Ntlha e nang le pherese e behang ke mofuta oa ho ba le mokhoa o behiloeng oa ho ts'ehetsa moqomo oa ho potoloha ha o ntse o tsitsitse lehong - sephara, se fanang ka botsitso bo eketsehileng. Ho fapana le likatse tse tloaelehileng tsa bolo, li tlil'o nkuoa ka matlong a ka hobeloang habonolo ke meaho ea mechi.

Moralo oo o tiisa hore ho tsamaisana ho ntse ho tiisa le hore moqomo o lula o tsitsitse nakong ea ts'ebetso. Ka tloaelo, lipere tsa phaering li entsoe ka tšepe e matla ea tšepe kapa e nang le bolo ea tšepe e phahameng, 'me li na le bolo ea boenjiniere bo tsamaisoang ke radiation le afyal.

Mefuta e tloaelehileng ea Flange ea Flae ea Flae e kenyeletsoa:

-

Lipere tse 2-Bolt Frantings: Morero o kopanetsoeng o loketse leseli la lits'ebetso tsa mahareng.

-

Likarolo tse 3-Bolt flangering tse 3

-

Lipere tse 4-Bolt freeenge: E entsoe bakeng sa tikoloho ea indasteri e boima le litlhokahalo tse phahameng.

Boholo ba flange li fumaneha ka mekhoa ea ho tiisa libapali, li-pomps, lisebelisoa tsa temo, shaft ea motlakase e hloka ho tšehetsoa le likhohlano tse nyane.

KAMOO E SE ETSANG:

Ka har'a matlo, kenya letsoho le leholo (ka tloaelo ho ts'oaroa ka bolo e tebileng) ho lumella moqomo hore a qale ka bolokolohi. Ho nyoloha hamonate ho na le tšusumetso e tsamaeang le ho ba thata

Ho etsa joalo ho ka kenyelletsa likarolo kapa ho beha litlolo tse koahelang le tse thusang ho boloka moqomo tlas'a meroalo e fapaneng le maemo a sebetsang. Sena se etsa hore ho be bonolo ho boloka le tšoarella ebile ho le bonolo ho se boloka, esita le lits'ebetso tse tlhokomelong e phahameng.

Hobaneng ha litšoantšo tsa hae tsa ho hloka litšoantšo li le bohlokoa lits'ebetsong tsa indasteri?

Bokhoni ba litšoantšo tse lokolotseng ho ntlafatsa katleho ea katleho ea ts'ebetso le ho phela hate. Ka ho fana ka tšehetso e tsitsitseng bakeng sa ho potoloha mekhahlelo, ba fokotsa khohlano, fokotsa tahlehelo ea matla le lisebelisoa ho tsoa ho thothokiso e feteletseng le ho roala.

Melemo ea bohlokoa ea ho sebelisa litšoantšo tsa lifoto:

| Tšobotsi | Tlhaloso | Rua molemo |

|---|---|---|

| Matla a phahameng a mojaro | E ts'ehetsa mojaro oa mahlaseli a mabenyane le a axial. | E atoloha bophelo ba mechini. |

| Ho hlohlona habonolo le ho hokahanya | Likoti tse tlotsitsoeng pele li lumella ho kenngoa ka potlako. | E nchafatsa nako ea kopano le litšenyehelo tsa tlhokomelo. |

| Ho itlhopakisa | Fumaneha ka tšepe e se nang steel kapa variants. | E loketse libaka tse thata kapa tse se nang metsi. |

| Phokotso ea vibration | E boloka e amoheloe ke shaft e otlolohileng ka tlase tlasa motsamao. | Thibela ho se be le lerata le mochini. |

| Ts'ireletso e tiisitsoeng | Lerōle le litiro tsa mongobo li tiisa ts'ebetso e hloekisitsoeng. | Fokotsa tšilafalo le ho apara. |

Hobaneng indasteri e itšetlehile ka lipehelo tsa flaering:

-

Temo: Bakeng sa literekere, metjhaba ea kotulo, le lipompo tsa nosetso moo ho thata.

-

Ho etsa tlhahiso: Tsamaisong ea Convey, matsoho a tsamaisang thepa le merobo ea roboto le mela e sephutheloana e hlokang ho potoloha ho potoloha ka boikemisetso bo fokolang.

-

Litsamaiso tsa Hvac: Ho ts'ehetsa balateli le lisosa tse sebetsang tlasa ho potoloha ha lebelo le tsoelang pele.

-

Likoloi tsa likoloi le lipalangoang: Litšebeletso tsa ACVLE le litsamaiso tsa phetisetso le phetiso li hloka ho hloka tlhompho le botsitso tlasa mojaro o boima.

Ntle le likhama tse phetoang hantle, lits'ebetso tsena li ne li tla ba le bothata bo eketsehileng, ho senya le ho roala hape - qetellong ea ts'ebetso ea ts'ebetso.

U ka khetha joang ho etsa kopo e nepahetseng bakeng sa kopo ea hau

Ho khetha setsoalle se nepahetseng ho itšetleha ka mofuta oa mojari, maemo a tikoloho, boholo ba tikoloho le lebelo la ho potoloha. Ho utloisisa litekanyetso tsena ho thusa ho tiisa hore ho na le khatello ea matla ho khona ho sebetsa ka mokhoa ha o ntse o tsoela pele ho sebetsa.

LITLHAKISO TSA BOTSOALLE:

-

SHARL bophara: Bore ea ka hare e lokela ho tšoana le boholo ba sekhahla ka mokhoa o hlakileng ho thibela ho thibela ho thibela ho thibela ho thibela ho thibela ho thibela ho senya kapa ho silafatsa tšebeliso.

-

Litlhokahalo tsa mojaro: Nahana ka majaro a radial kapa axial (parallel). Mechine e mengata e na le methapo e meholo kapa e hlokometsoeng likotoana tsa mahala.

-

Sebopeho sa maiketsetso:

-

Itloaetse tšepe:Matla a phahameng le a loketseng libaka tsa indasteri.

-

Ts'epe e sa beng le mabali:Corsuon-e thibelang, e loketseng bakeng sa ts'ebetso ea lijo kapa ts'ebeliso ea metsing.

-

Ho hohela matlo a Thermoplanes:Tse bobebe le ho loantšana le lik'hemik'hale, e loketseng indasteri ea bohloeki.

-

-

Mofuta oa Bohlokoa: Lipehelo li ka tla ka li-rabara tsa rabara kapa tsa tšepe ho itšireletsa khahlanong le lerōle, metsi le tahlehelo ea lubricatang.

-

Phetoho ea ho ntlafatsa: Khetholla pakeng tsa 2-bolt, li-patens tse 3 kapa tse 4-bolt

-

Ho sebetsa ka lebelo le mocheso: Litsela tse etselitsoeng ho potoloha ka lebelo le tšoere ka mocheso le li-lubrictric tse khethehileng ho thibela ho hoholo.

Malebela a ho lokisa bakeng sa tšebeliso ea nako e telele:

-

Litlolo khafetsa: Sebelisa mafura a moetsi-e khothalelitsoeng ho thibela lebitso la tšepe.

-

Licheke tsa Alignment: Nako le nako li netefatsa hore shaft le matlo li lula li hokahane ka nepo.

-

Seal Tlhahlobo: Beha litiiso tse bonts'ang matšoao a ho roala kapa ho tloha ho boloka ts'ebetso ea mahala ea litšila.

-

Ho lekola mocheso: mocheso o feteletseng o ka supa ho khutsufatsa kapa ho ts'oaroa ka bongata.

Ho lokisa ka nepo ho ka holisa bophelo ba ho becha ka lilemo, haholo-holo ho fokotsa litšenyehelo tsa nako ea nako ea phomolo le ho li lokisa tsamaisong ea indasteri.

LIHLOOHO TSE BOTSOANG HANGATA KA LIHLOOHO TSE KHOLO

Q1: Ke eng e bakang ho se atlehe pele ho nako?

Ka tloaelo ho tloha ka nako ea pele ho nako ha ho etsoa hampe, mabopo a fosahetseng, tšilafalo kapa mojaro o feteletseng o fetang bokhoni ba ho beoa. Ho fumana tlhokomelo khafetsa le ho kenya ka nepo ho ka thibela litaba tsena.

Q2: Ho na le lijong tsa ho hloka litšoantšo hangata hakae?

Liphetoho tsa Lubriction li itšetlehile ka tikoloho ea ts'ebetso le maemo a ho tsamaisa. Ka lebelo le phahameng kapa lits'ebetsong tse phahameng tsa mocheso, beke le beke kapa khoeli le khoeli e ka ba teng. Libakeng tse hloekileng, tse bobebe, tse bobebe, lubrication e 'ngoe le e' ngoe likhoeli tse 3 ho isa ho tse tšeletseng li lekane.

Ho aha litsamaiso tse tšepahalang tse nang le mafati a monate a nide

Lits'oants'o tsa mahalafo li ka hlaha tse nyane ha li bapisoa le mechini eo ba e sebeletsang, empa karolo ea bona ea ts'ebetso e ka feteletseng. Ho tloha ka ho boloka litšebelisano tsa ho fokotsa molimo le tahlehelo ea matla, likarolo tsena li bohlokoa ho botsitso ba maemo a fapaneng a khoebo.

HoTloaelo, re etsa likotoana tsa phallo ea boenjiniere tse hlophisitsoeng tse etselitsoeng ts'ebetso ea nako e telele le tlhokomelo e tlase ho lits'ebetso tse fapaneng tsa indasteri ea indasteri ea indasteri. Lits'oants'o tsa rona li kopanya lisebelisoa tse tsoetseng pele, theknoloji e nepahetseng le lits'iseng tse tiisang le litsamaiso tsa ho tiisa tšebetso ho netefatsa ts'ebetso e sa fetoheng le tlasa maemo a thata.

Haeba u batla ho ntlafatsa katleho ea lisebelisoa tsa hau tsa lisebelisoa kapa ho hloka thuso ho khetha ka mokhoa o nepahetseng bakeng sa mochini oa hau,iteanye le ronaKajeno. Sehlopha sa rona sa tekheniking se se se loketse ho u thusa ho khetha tharollo ea hau ea kopo ea hau - Ho netefatsa hore o tla ts'epa.