Ho na le boemo bo monate ba ho ntlafatsa maqhubu joang?

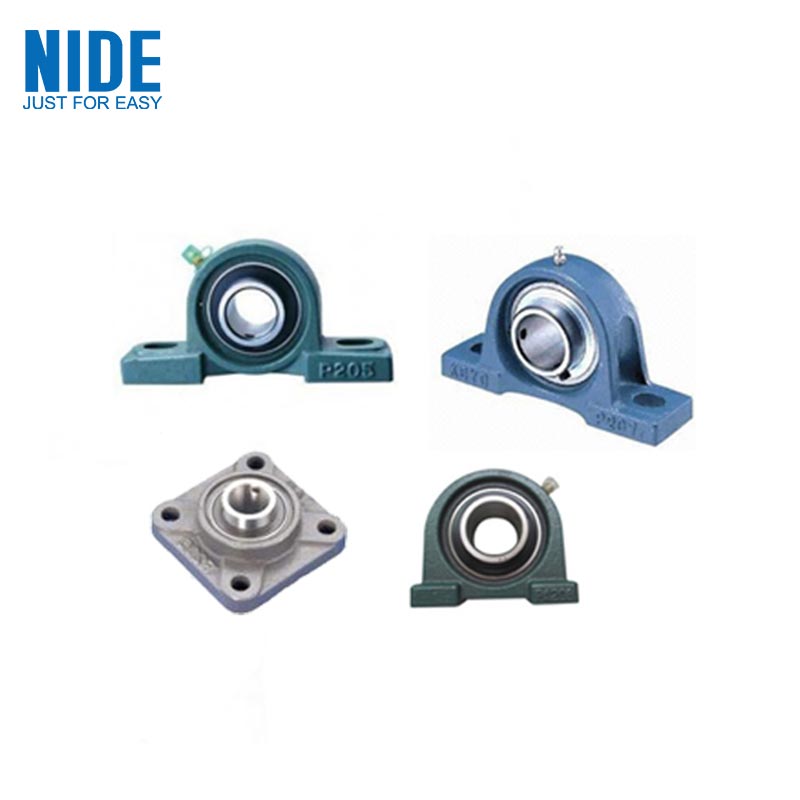

Lipere tsa Photoeringke likarolo tse khethehileng tsa boikarabello tse etselitsoeng ho tšehetsa li-shafts tse potolohang ha li fokotsa likhohlano lipakeng tsa likarolo tse tsamaeang tsa mechini ea indasteri. Ba enjene ho mamella mojaro oa bohlokoa, ho hana ho roala, 'me ba boloke alignment e nepahetseng lits'ebetsong tsa mochini. Ho fapana le likarolo tse tloaelehileng, lipina tsa flaee tse kenyangnge le ho tsitsa tse ntlafatsang le ho nolofatsa ts'ebetso ea ho kenya likokoana-hloko.

Lipheo ea Bohle, 'me li fapana joang le likopo tse tloaelehileng?

Lipere tsa hae tsa ho lokolla ke li-portings tse ntseng li roll ka foreiloeng tsa ho hola li hokahantsoe ka kotloloho ho ho belisa matlo. Moralo ona o fana ka mekhoa e sireletsehileng le e nepahetseng ea ho nyoloha liforeimi, ho tlosa litlolo tsa maqheka le ho ntlafatsa tsitsi e potolohileng. Hangata li entsoe ka tšepe e matla e phahameng, tšepe e nang le seqhetsoana kapa sengoloang ho fana ka sekhoma-pele maemo a fapaneng a fapaneng.

Litšobotsi tsa bohlokoa tse khethollang li kenyelletsa:

-

Ho hokahana le ho khema ka mokhoa o ikhethileng: ho fana ka likhoele tse bonolo ha u hloka mabokose a ntseng a eketseha.

-

Tsamaiso ea moroalo: e ntlafalitsoe ho sebetsana le mojaro oa mahlaseli a radial le a nang le axial, ho latela moralo o behang mahala.

-

Ho nepahala ho hokahanyang: ho boloka ho feto-fetoha ha lihlong, ke ntho e kopanyang likhakanyo le likarolo tse ntlafatsang ts'ebetso.

-

Ho sitisoa ke likopo tse fapaneng, ho kenyelletsa sistimi ea ho tsamaisa, mochini oa temo, lits'ebetso tsa koloi le lisebelisoa tsa indasteri le lisebelisoa tsa indasteri.

Li-paramente tse qaqileng tsa mahlale a lifoto:

| Paramente | Tlhaloso |

|---|---|

| Mofuta oa ho beha | Bolo e nang le bolo, roller e na le ho tsamaea, kapa sleeve reheletsoeng |

| Lintho tse ntle | Lahlela tšepe, tšepe e se nang mabili, kapa polasetiki ea boenjiniere |

| Bore Mofuta oa Bore | E tloaelehileng ho tloha ho 12mm ho 100mm (boholo ba tloaelo e teng) |

| Bophara ba kantle | 32mm ho 150mmm |

| Botenya tse ntle | 5mm ho 20mm |

| Matla a motšeha (matla) | 5000 n - 50,000 n |

| Matla a motšeare (stetic) | 6000 n - 60,000 n |

| Ho sebetsa molumo oa mocheso | -30 ° C ho 150 ° C |

| Mokhoa oa Librication | Mefuta e metle e khanyang, e lubeloang ka oli, kapa ho itsafatsa |

| Likhetho tsa ho holisa | Phoso e nne-bolt malatetsi, a mabeli-bolt flange, kapa flange |

Likotoana tsa phihlello li sirelletsa ho leka-lekana ho leka-lekana bokhoni ba tšepe, phokotso ea likhohlano, le boiketlo ba tlhokomelo. Ho khetha mofuta o nepahetseng ho latela litlhoko tsa kopo joalo ka mofuta oa thepa, maemo a tikoloho le lebelo la ts'ebetso.

Hobaneng ho na le likopo tsa ho fuputsa tse bohlokoa bakeng sa katleho ea indasteri le mochini o bolelele?

Mechine ea indasteri e tlasa ho sisinyeha ho tsoelang pele moruong, e phahamisetsa khatello ea kelello le thollo. Khetho e sa lokang e ka lebisa ho ts'ebetso ea ts'ebetso, tsitsipano ea lisebelisoa le Downtine e sa tsejoeng. Lits'oants'o tsa Flange Liroparo tsena ka ho fana ka likotsi tsena ka ho fana:

-

Khohlano e fokotse: fokotsa tahlehelo ea matla le ho fokotsa litšenyehelo tsa ts'ebetso.

-

Ts'ehetso e ntlafalitsoeng ea mojaro: E tsamaisa mojaro o ratoang le axial, ho thibela ho se atlehe pele ho nako.

-

Khokahano ea mantlha: e tsamaisana le mechini, ho fokotsa li-shafts, gear le pulleys.

-

Phokotso ea vibrate le ho fokotsa lerata: ho ts'ehetsa mesebetsi e matla ka lebelo le phahameng kapa lits'ebetsong tse phahameng.

-

Mokhoa oa ho hlokomela: Folangs e kopaneng e nolofalitseng ho kenya le ho ikhetholla ntle le koluoa ea mechini e pharalletseng.

Indasteri e itšetleha ka likotoa tsa mahala ka lebaka la bokhoni ba ho ntlafatsa ts'ebetso ea mochini, fokotsa nako ea nako ea nako, le ho holisa bophelo. Mohlala, mela ea Kopano ea Likoloi, - Likopano tsa Kopano li boloka ho hokahana ha li-thata tlas'a moroalo o boima, ho netefatsa boleng bo loketseng ba sehlahisoa. Lisebelisoa tsa temo, ba mamella tikoloho e litšila, ho kenyelletsa le tlhahiso ea lerōle, metsi le mocheso oa khatello.

Hobaneng u khetha litaba tse nepahetseng ka ho fetesisa:

Ho khetha ho tseba ho ts'oanang le litlhoko tsa tikoloho, maemo a tikoloho le lebelo la ts'ebetso li bohlokoa. Ho etsa lintho tse sa nepahalang kapa khetho ea lintho tse hlokahalang ho ka fella ka:

-

Pele ho nako ho feta tekano le ho hloleha

-

Ho sebelisa matla a matla a matla ka lebaka la likhohlano

-

Tšenyo e khopisitsoeng ea vibration ho hokahana

-

Lisebelisoa tse phahameng tsa tlhokomelo le litšenyehelo

Ka ho tsetela lipapatsong tsa phihlello tsa enjene, basebetsi ba indasteri ba ka fihlela ts'ebetso e tšepahalang, e tšoarellang ka mefuta ea mechine e fapaneng ea mochini.

Ho sebetsa ka hare ho nako ho ntse ho etsa mosebetsi oa mofuta ofe, 'me ho na le melemo efe ea bona ea bohlokoa?

Ts'ebetso ea litšoantšo tsa mahala ka ho fana ka sebopeho sa likhohlano tse tlase lipakeng tsa tšehetso e potolohang le ts'ehetso ea boemo bo phahameng. Lisebelisoa tsa ho rokella kapa li-roller-tsamaisang mojaro, ha chrae e tiisa boemo le botsitso. Ho utloisisa mechini ea bona ea ts'ebetso ho thusa hoenteers ho lokisa ts'ebetso ea mochini le ho qoba likotsi tse tloaelehileng tsa tlhokomelo.

Melao-motheo ea Bohlokoa:

-

Tsamaiso ea moroalo: Ho batloa ka ho hlaka ka mokhoa o hlakileng le ho tsamaisa matla sebakeng se phahameng, ho thibela maikutlo a khatello ea maikutlo a sithabetseng.

-

Phokotso ea likhohlano: Lona mekhoa e fokotsang khohlano lipakeng tsa moqomo lipakeng tsa moqomo le matlo.

-

Ho tsitsitse ha ho potoloha: Ho thibela morao ho pota, ho latela lintho tse lumellanang le ho potoloha hahe le ho potoloha hantle.

-

Ts'ebetso ea Tlhokomelo: Litefiso tsa lubrican kapa lisebelisoa tsa boithatelo li fokotsa maqhubu a ts'ebetso ea tlhokomelo ea tlhokomelo.

Melemo ea mantlha ea likotoana tsa flange:

-

Ho le tšoarella: Ho hahuoa ho tsoa linthong tse matlafatsang tse phahameng ho mamella tšebetso ea mosebetsi o boima.

-

Ho sitisoa ke ho sitisoa ho otlolohileng, ho otloloha, tse otlolohileng le tse otlolohileng.

-

Ho ba le Phetoho ea Ts'ebetso: E fokotsa ho roala likarolo tse haufi le mechini e haufi.

-

Ho kenya ka mokhoa o bonolo: Ho phefumoloha ho tlosa tlhoko ea meaho e rarahaneng ea meroho e rarahaneng.

-

Kopo e theko e boima: Litsela tse atolositsoeng

Mehlala e Tloaelehileng ea Lihlahisoa:

-

Libano tsa Conveyr ho Lihlahisoa tsa Tlhahiso

-

Mechine ea temo le bakotuli ba koluoa

-

Li-Shafts tsa koloi le litsamaiso tsa thepa

-

Balateli ba indasteri, lipompo le compressors

LIPOTSO TSE BOTSOANG HANGATA (FAQS):

Q1: Ho lokela ho lokisoa hangata hakae lits'ebetsong tse phahameng tse phahameng?

A1: Khafetsa khafetsa e latela lebelo la ts'ebetso, mojaro le tikoloho. Ka tloaelo, likopano tse lutseng - li hloka tlhahlobo ka lihora tse 500-1000 tšebetso ea tšebetso ea tšebetso. Libakeng tse lerole kapa tse nang le metsi, lubrication khafetsa e khothalelitsoe. Khoele e nepahetseng e fokotsa likhohlano, e thibela ho fetella, le ho ba le nako e telele.

Q2: E ka sebelisoa lifoto tse ntle ho likopo tse phahameng tsa mocheso?

Al Ho bohlokoa ho khetha ho be le litiiso tse nepahetseng le lubrication e bonang keketseho ea litlolo le ho thibela ho sobricant.

Mekhoa ea Bokamoso le Bohlokoa ba Liindasteri le Bohlokoa ba Likarolo tsa Bofokoli

Karolo ea lifoto tsa sejoale-joale e ntse e fetoha liindasteri, liroboto tsa tlhahiso ea litsebi tsa lebelo le matla. Mekhoa ea Bokamoso e kenyelletsa:

-

Lisebelisoa tse tsoetseng pele: Nts'etsopele ea li-berpic tsa lefutso le tse nang le likarolo ho fokotsa boima le ho eketsa khatello ea mocheso.

-

Marang-rang a Smart: Ho kopana ha likelello bakeng sa ho beha leihlo nako ea nako ea nako ea nako ea sebele ea mocheso, Viroation le mojaro oa ho boloka tlhokomelo e boletsoeng esale pele.

-

Khokahano e tsitsitseng: Ts'ebeliso ea li-eco-libribits tse botsoalle le lisebelisoa tsa boithati ho fokotsa tšusumetso ea tikoloho.

-

Khokahano e ntlafalitsoeng Tlhahisoleseling: Boreleli bo bobe bakeng sa lebelo le phahameng, ba imetsoeng maemong le lits'ebeliso tse ling tse fapaneng ho ntlafatsa ts'ebetso.

Basebetsi ba indasteri ba ntse ba ea pele ba lokisa mehala ea lifoto tsa lapeng ho fihlela linako tsohle, katleho ea matla ea matla le boikarabello ba lisebelisoa. E le hore ho fana ka thepa ea ho etsa ho hola, likoura tsa mahala e ntse e le tharollo e tšepahalang ea ho fokotsa likhang tsa ts'ebetso ha u ntse u tšehetsa lits'ebetso tsa tšebetso.

Phetha: Litefiso tsa ho lokoloha e le sekhutlo sa mochini oa indasteri

Lits'oants'o tsa phihlello li fana ka botsitso bo sa tsitsang, ho nepahala ha mechini ea li indasteri. Ka ho fokotsa likhohlano, ho tšehetsa mojaro o rarahaneng, le ho tsamaisana hantle le ho tsamaisana le lihlong, li ntlafatsa ts'ebetso ea ts'ebetso ea tšebetso le lefutso e sebetsa hantle.Tlama'Me mefuta e fapaneng ea lifoto e kopanya lisebelisoa tse matla, boenjiniere bo nepahetseng, le boenjiniere bo ntlafatsang ho fihlela litlhoko tsa indasteri tse hlokang haholo. Bakeng sa tlhaiso-leseling e batsi kapa ho khetha lintlha tse ntle tsa ho fana ka chelete bakeng sa likopo tse tobileng,iteanye le ronaKajeno.